| Sign In | Join Free | My entremaqueros.com |

|

| Sign In | Join Free | My entremaqueros.com |

|

| Categories | Laboratory Ball Mill |

|---|---|

| Brand Name: | TENCAN |

| Model Number: | QXQM-8 |

| Certification: | CE ISO |

| Place of Origin: | Hunan, China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 150 sets per month |

| Delivery Time: | 10-15 working days after getting full payment |

| Packaging Details: | Carton or Plywood Case |

| Product Name: | Laboratory Dual Planetary Ball Mill |

| Model No.: | QXQM-8 |

| Total Volume: | 8L |

| Max Capacity: | 2.64L |

| Rotate Speed: | 70-580 rpm |

| Voltage: | 220V-50Hz or 110V-60Hz |

| Power: | 1.5KW |

| Speed Control: | Frequency Converter |

| Type: | Ball Mill |

| Company Info. |

| Changsha Tianchuang Powder Technology Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Complete Functions Full-directional Laboratory Ball Mill for Chemical Engineering and R D Institutions

Overview

Full-Directional Laboratory Planetary Ball Mill

The Full-Directional Laboratory Planetary Ball Mill is essential equipment for processing advanced materials, performing fine grinding, powder mixing, nano-powder synthesis, new product development, and small-batch production. Tencan's planetary ball mill offers compact design, high efficiency, quiet operation, and comprehensive functionality. It serves as an ideal solution for R&D institutions, universities, and corporate laboratories requiring ultra-fine powder samples. Featuring four independent grinding stations, the system enables simultaneous processing of up to four samples. When equipped with specialized vacuum milling jars, it also supports sample preparation under controlled vacuum conditions.

Operating Principle

The Full-Directional Laboratory Ball Mill incorporates four grinding stations mounted on a single rotating disc. As the main disc rotates, each grinding jar simultaneously revolves around its own axis while performing 360-degree planetary motion. This compound movement generates high-speed impact and friction forces through the grinding media, ensuring efficient particle size reduction and homogeneous mixing. Compatible with both dry and wet processing methods, the equipment handles diverse materials with varying initial particle sizes, achieving final fineness down to 0.1 micrometers. It finds extensive application across geology, mining, metallurgy, electronics, construction materials, ceramics, chemical engineering, light industry, pharmaceuticals, and environmental protection sectors.

Technical Features

| Drive Mode | Gear drive and belt drive |

| Operation Mode | Two or four grinding tanks working together |

| Maximum Loading Capacity | 2/3 of the capacity of milling tank |

| Feeding Size | Soil material≤10mm, other materials≤3mm |

| Output Granularity | Smallest 0.1 μm |

| Rotational Speed Ratio | 1/2 |

| Max. Continuous Operating Time | 48hours |

| Optional Modes of Speed Control | Frequency conveter and automatic timing control |

| Materials of Jar | Stainless steel, agate, nylon, corundum, zirconia, etc. |

Technical Parameters

| Parameters of Full-Directional Laboratory Ball mill | |||||||

| Type | Power (KW) | Voltage (V) | Dimension(mm) | Revolution Speed (rpm) | Rotation Speed (rpm) | Total Timing (min) | Alternating Run Time of Forward & Reversal Rotation (min) |

| QXQM-0.4 | 0.75 | 220V-50Hz | 1100*750*825 | 35-335 | 70-670 | 1-9999 | 1-999 |

| QXQM-1 | 0.75 | 220V-50Hz | 1100*750*825 | 35-335 | 70-670 | 1-9999 | 1-999 |

| QXQM-2 | 0.75 | 220V-50Hz | 1100*750*825 | 35-335 | 70-670 | 1-9999 | 1-999 |

| QXQM-4 | 0.75 | 220V-50Hz | 1100*750*825 | 35-335 | 70-670 | 1-9999 | 1-999 |

| QXQM-6 | 0.75 | 220V-50Hz | 1100*750*825 | 35-335 | 70-670 | 1-9999 | 1-999 |

| QXQM-8 | 1.5 | 220V-50Hz | 1220*900*960 | 35-290 | 70-580 | 1-9999 | 1-999 |

| QXQM-10 | 1.5 | 220V-50Hz | 1290*900*960 | 35-290 | 70-580 | 1-9999 | 1-999 |

| QXQM-12 | 1.5 | 220V-50Hz | 1220*900*960 | 35-290 | 70-580 | 1-9999 | 1-999 |

| QXQM-16 | 3 | 380V-50Hz | 1530*1070*1220 | 30-225 | 60-510 | 1-9999 | 1-999 |

| QXQM-20 | 4 | 380V-50Hz | 1700*1100*1200 | 25-215 | 50-430 | 1-9999 | 1-999 |

| QXQM-40 | 5.5 | 380V-51Hz | 1900*1450*1480 | 20-195 | 40-390 | 1-9999 | 1-999 |

Accessories of Mill Jars & Balls

Available Mill Jars:

304 stainless steel mill jar, 316 stainless steel mill jar, tungsten carbide mill jar, agate mill jar, alumina ceramic mill jar(also called corundum mill jar), zirconia mill jar, nylon mill jar, polyurethane mill jar, mill jar (PTFE), and etc.

| Recommendation For Matching Solutions About Mill Jars & Materials | |

| Categories of Materials | Recommended Mill Jars |

| Soil and other Materials which are not allowed with any impurity | Agate mill jar |

| Metal & nonmetal materials which are not allowed with any impurity | Zirconia mill jar |

| High hardness materials like diamond, tungsten carbide | Tungsten carbide mill jar |

| Strong add & alkali materials or other materials at high temperature | PTFE mill jar |

| Iron ore materials with lower impurity sensitivity | 304 Stainless steel mill jar |

| Pigment or other materials with later process under high temperature | Nylon mill jar |

| Aluminum materials like ceramic glaze | Corundum mill jar |

| Electronic materials like lithium battery | Polyurethane mill jar |

| Easily oxidized materials or some special materials which need to be protected under special atmosphere. | Vacuum mill jar |

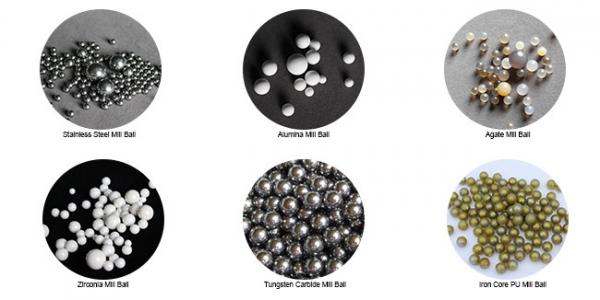

Available Mill Balls:

304 stainless steel mill balls, 316 stainless steel mill balls, tungsten carbide mill balls, agate mill balls, alumina balls, zirconia mill balls, and etc.

| References About Grinding Medias & Materials | ||

| Materials of Grinding Media | Hardness (Mohs) | Features |

| Zirconia Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

| Stainless Steel Balls | ≥6.0 | Wear-resistant, general corrsion resistance, high temperature resistance. |

| Agate Balls | ≥7.0 | Super wear-resistance, used for medicine,food and other materials which can not be contaminated with metal, corrosion, and high temperature resistance. |

| Alumina Balls | ≥8.5 | Wear-resistant, corrsion resistance and high temperature resistance. |

| Tungsten Carbide Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

| Matching Solutions for Mill Jars & Balls | |||||

| Items | Agate Balls | Alumina Balls | Stainless Steel Balls | Zirconia Balls | Tungsten Carbide Balls |

| Agate Mill jar | √ | ||||

| Corundum Mill Jar | ▲ | √ | ▲ | ||

| Stainless Steel Mill Jar | √ | ||||

| Zirconia Mill Jar | ▲ | √ | |||

| Nylon Mill Jar | ▲ | √ | |||

| PTFE Mill Jar | √ | ▲ | |||

| Polyurethane Mill Jar | √ | ▲ | |||

| Tungsten Carbide Mill Jar | ▲ | √ | |||

| √ means: most suitable ▲ means: suitable | |||||

TENCAN Planetary ball mills are available in different versions.

Please refer to our website www.lab-mills.com for a complete overview of the different performance features.

|