| Sign In | Join Free | My entremaqueros.com |

|

| Sign In | Join Free | My entremaqueros.com |

|

| Categories | Ridge Cap Roll Forming Machine |

|---|---|

| Brand Name: | BEST |

| Certification: | CHINA |

| Place of Origin: | CHINA |

| MOQ: | 1 set |

| Price: | USD6000-10000 |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 sets/month |

| Delivery Time: | 30 work days |

| Manual Decoiler 7.5KW Roofing Sheet Making Machine With Hydraulic Cutting: | 380V 50Hz 3phases |

| Condition: | New |

| Use: | Roof/wall |

| After-sales service provided: | Engineers available to service machinery overseas |

| Control system: | PLC(imported Brand) |

| Usage: | sed As Roof Panel In Steel Construction |

| Company Info. |

| Cangzhou Best Machinery Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

WHY CHOOSE US

1) Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We

need your machines running in order to keep your business running.

2) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit.

3) Q:Can you be responsible for transport?

A:Yes,please tell me the destination port or address.we have rich experience in transport.

4) Q:Can you supply the raw materials?

A:Yes,we can supply the galvanized steel coil,galvalume steel coil,color steel coil,and aluminum coil.

Ridge cap roll forming machine

Passed CE& ISO certification

PLC control system

More professional, economic,high quality

Technical data of metal roof tile roll forming machine

| Suitable material | color steel sheet;0.3-0.7mm, |

| Working speed | about1.5-5m/min |

| stress | 235MPa,345MPa,550MPa. |

| Power | Main motor power: 5.5 Kw(Depend on final design) |

| Hydraulic station power: 4Kw(Depend on final design) | |

| Material of forming rollers | No.45 steel, plated with chrome on surface. |

| Material of cutter,pressing die | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of shaft | High quality 45# steel, Roller grinder milling. |

| Shaft diameter | 72mm |

| Controlling system | Mitsubishi PLC & converter |

| Total weight of machine | About 9500KGS |

| Machine’s size | about 18m×1.8m× 1.5m (Depend on final design) |

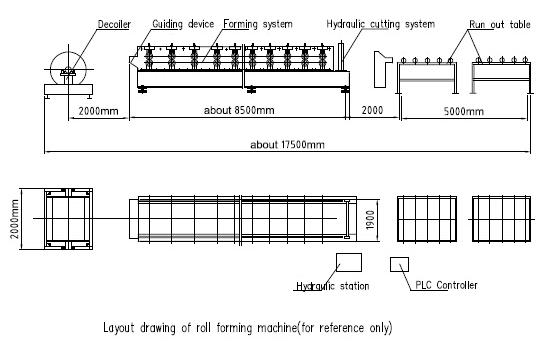

Layout drawing of machine

Our Roll Forming Machine’s advantages

1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome .to protect surface shiniing and strong

2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.and hardness 60 degree.

3. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

4. High precision: shafts for rollers are tooled by grinding machine. Rollers are CNC processed to ensure precision performance.

5 .automatic PLC : introduced Mitsubishi PLC with touch screen ,inverter,transformer.

6. powerful driving system: big inch train,or gear box driving system.

6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines.

producing process:

Product:

Application

|