| Sign In | Join Free | My entremaqueros.com |

|

| Sign In | Join Free | My entremaqueros.com |

|

| Categories | Rack Roll Forming Machine |

|---|---|

| Brand Name: | Dingbo |

| Model Number: | DBRS |

| Certification: | ISO CE SGS |

| Place of Origin: | Jiangsu, China |

| MOQ: | 1 set |

| Price: | USD30,000-50,000 |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets /month |

| Delivery Time: | Shipped in 30-70 days after payment |

| Packaging Details: | Export standard sea package with film and steel |

| Product name: | Automatic Shelf Rack Upright Roll Forming Machine with Gearbox and Cr12 Roller Material |

| Roller material: | 45# Steel |

| Production Capacity: | 10-15m/min |

| Power(W): | 22 KW |

| Cutting blade material: | Cr 12 High Grade Steel |

| Shaft material: | High Grade No.45 Forged |

| Control system: | PLC(imported Brand) |

| Uncoiler: | Manual or hydraulic |

Automatic Shelf Rack Upright Roll Forming Machine with Gearbox and Cr12 Roller Material

Main features

Rack upright roll forming machine, rack column roll forming machine, rack roll forming machine, Rack post roll forming machine, rack roll forming machine, rack roll forming machine, rack column forming machine, rack post roll forming machine includes decoiler, feeding and levelling device, roll forming machine, flying saw cutter, run-out table, hydraulic system and PLC control system, etc. We produce series of machines for rack upright, column, beam, angle steel, and other racking profiles.

Working flow

Decoiling → Feeding → Press Machine → Roll forming → Hydraulic cutting-off → Run-out table

Technical parameters

| No. | Item | Specification |

| 1 | Can Formed Material | GI |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 50Hz 3Phase or as your requirement |

| 4 | Thickness of sheet (mm) | 2.0-3mm |

| 5 | Material width(mm) | As your requirement |

| 6 | Cover Width of the sheet after formed | As your drawing |

| 7 | The size of the roll forming machine | 9000mmx2000mmx1500mm |

| 8 | Speed | 8-15m/min |

| 9 | Diameter of shaft | 76mm |

| 10 | Weight of the Machine | 10000KGS |

| 11 | Material of rollers | C45 steel quenched and chromed |

| 12 | Motor brand | Siemens or Guomao |

| 13 | PLC | Siemens or Delta or Mitsubushi |

| 14 | Main motor power (kw) | 22kw |

| 15 | Press machine | High Speed 80Tons |

| 16 | Sizes adjustment | Manually Adjustable |

Machine components

Machine pic

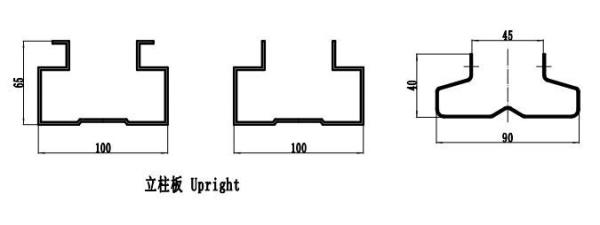

Profile drawing

FAQ

1. Does one machine can only produce one size?

Not exactly, it depends on which profile the customer want to

produce.

2. Do you have after-sales technical support?

Yes,we are happy to give advice and also have skilled technicians

available to maintain the machine overseas to customers’ workshop

if needed.

3. You are trading company or factory?

We are Manufacturer, and we export our machine by ourselves.

4. How long the machine could be made?

Normally speaking, high precision roll forming machine could be

made out with 40 working days.If you need machines in hurry, we can

make it for you less than a month.

5. Do you provide customized?

Sure, we can design the machine according to the requirement and

profile drawing you provide. Our engineers can offer the best

professional solution to our worldwide clients.

6. May we visit your factory?

Sure,Warmly welcome to our factory at any time.

7. How to visit your factory?

By high speed train from Shanghai to East Wuxi (Wuxi Dong station),

half an hour.

8. What's the warranty period?

12 months warranty period, starting from the date of the successful

installation and commissioning of the equipments at the Buyer’s

Installation site.

9. Can we arrange shipment?

Yes, sure, we can arrange shipment for our customers and provide door-to-door service.

Best Regards

Andy Yang

Director

Mobile/Wechat/Skype:0086 139 2126 2246

|