| Sign In | Join Free | My entremaqueros.com |

|

| Sign In | Join Free | My entremaqueros.com |

|

| Categories | Shutter Door Roll Forming Machine |

|---|---|

| Brand Name: | Sussman |

| Model Number: | SS-DR |

| Certification: | CE |

| Place of Origin: | Wuxi Jiangsu China |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | T/T L/C |

| Supply Ability: | 10 sets per months |

| Delivery Time: | 55-65 days after deposit |

| Packaging Details: | Standard packing |

| Material Thickness: | 0.7-1.2mm |

| Forming Speed: | 8-10 m/min |

| Main Motor Power: | 7.5Kw |

| Forming Stations: | 12 stations |

| color: | customized |

| Condition: | new |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Australia Type Shutter Door Production 12 Stations Roll Forming

Machine PLC Control System

Door Rail Technical Parameter

1. Steel Sheet Thickness: 1.5-2mm (depend on requirement )

2. Transmission way: single chain

3. Transmission material: 45# steel, high frequency quenching,

circular pitch: 38.1, number of teeth:13

4. Material of blad: Cr12, quenching treatment

5. Capacity of Decoiler: 3 ton passive decoiler

6. Forming Speed: 8-10m/min

7. Roller Groups: 12 stations upper and 16 stations down

8. Roller Material: Cr40 steel, high frequency quenching treatment,

HRC58-62

Door Rail Main Components

| Components of Machine and Main Description | ||

| Components of Machine | Main Description | |

| 1 | Automatic hydraulic uncoiler(according the machine and your requirement) | 1.Loading Capacity:Max:10 Tons |

| 2.Main motor:5 KW | ||

| 3.Coil Width:Max:1250mm | ||

| 2 | Entry Bench | Guiding the raw material into the roll forming machine smoothly |

| 3 | Feeding Section with guide | Easily for the raw material entry |

| 4 | Main forming machine | Forming the panel according your requirement |

| 5 | PLC control system | Automatically control the quantity of sheet, cutting length, step length |

| 6 | Cutting blade | Cutting the panel automatically |

| 7 | Product Rack | Can adjustable according the length of the panel (3 units) |

| 8 | Pressing device | Pressing the panel automatically |

| 9 | Mesh cover above roll former(optional) | Avoid hand go inside the forming machine |

Advantage for Door Rail

| Feature: |

| 1. Cutter Material: Cr12MoV1 mould steel with heat treatment |

| 2. Shaft Material: 40Gr mould steel with heat treatment |

| 3. Roller Material: 40Gr mould steel with heat treatment, hard Chrome Coated |

| 4. Have fashionable, nice appearance and durable |

| 5. Delivery time: 30% deposit and balance before delivery |

| 6. Widely used in various industrial factory, villa building, civilian building, warehouse, etc |

7. We can manufacture various kinds of machines to satisfy our customer, you can also provided the drawings what you want or the samples, we will design the project for you accordingly |

Working Flow of Door Rail

Decoiler----Feeding and Leveling---Roll forming---Cutting---Run out

tables

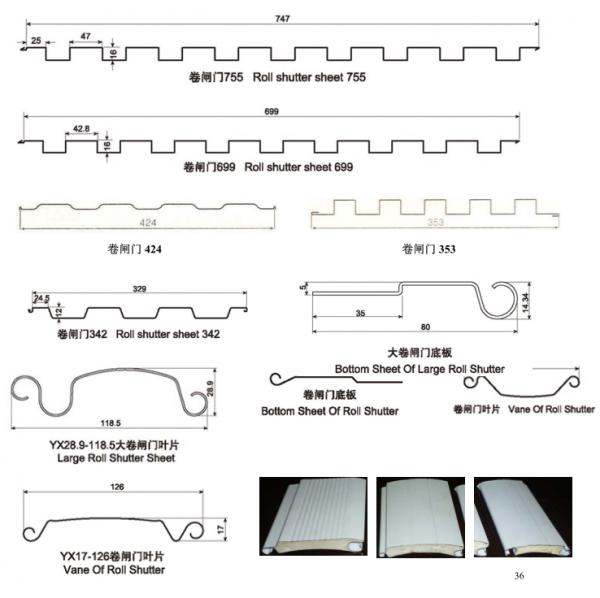

Profiles of Door Rail

Picture drawing

Loading Pics

|